In cold climates and while transferring temperature-sensitive products, loading arms have to retain heat for successful operation. Whether moving foodstuffs or fuel, gradual freezing and solidifying of product is liable to slow down operations when external temperatures dip. Insulation is the best defense against loading arm clogs while active and during downtime, but choosing the right heating package requires a few considerations.

An insulation, or heating, solution should provide a non-restrictive fit. This means that any jacketing should allow full and correct range of motion, while at the same time offering superior heat retention and durability. To meet these benchmarks, jacketing should be custom designed for the loading arm configuration and application using high-performance materials like low-density fiberglass and Teflon®. The blueprint for an insulation package is a strong start, but the method of heat generation must be determined, as well.

Loading Arm Heating Options

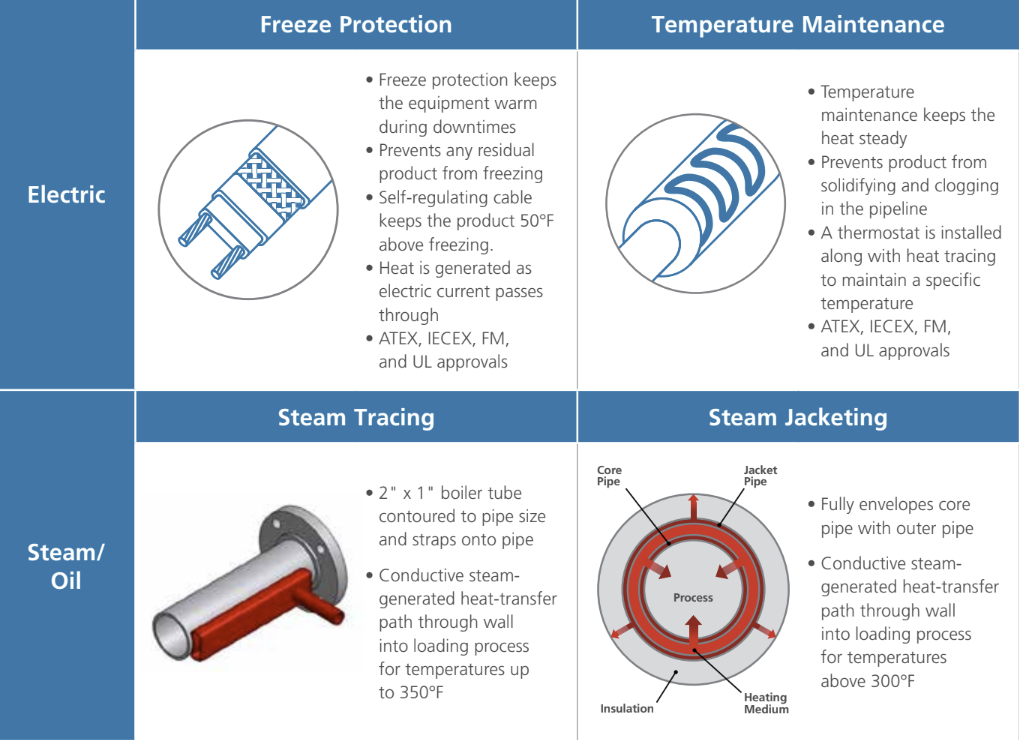

OPW’s Custom Insulation Packages are built to spec for each arm with insulation material that is delivered to the jobsite ready for field assembly. Each package could feature one of four heating options: freeze protection, temperature maintenance, steam tracing or steam jacketing. Different heating options offer distinct benefits, and we have laid them out in the chart below:

No matter the heating option, it is recommended that the insulation be installed after the arms are set in place to avoid damage during rigging/installation. Custom Insulation Packages come with a detailed drawing that provides easy to follow step-by-step instructions. The installation can also be easily removed if and when loading-arm maintenance is required.

OPW Engineered Systems can provide insulation designed specifically for your loading arm, with superior heat retention, safety and the range of motion that the arm was designed to offer. Unlike field-applied insulation, these packages are completely removable and reusable, making them an ideal insulation solution. Click here for assistance in selecting the insulation and heating solution to meet the needs of your application.