Optimizing the performance, protection and safety of fueling, electrical and sewage access systems that are buried underground requires a balancing act. They must stand up to the daily wear and tear of foot and vehicle traffic, heat and rain in the summer and cold, snow, salt and snowplows in the winter, shifting ground and seismic events, with water intrusion a threat at all times. At the same time, they must allow easy access so that they can be reliably serviced, maintained, monitored and repaired.

Founded in 1980, Fibrelite, which was acquired by OPW in 2013, has helped set the global standard in designing and manufacturing fiber-reinforced plastic (FRP) composite components for fueling, electrical and sewage access and containment systems. The FRP manufacturing process gives Fibrelite products an unrivaled strength-to-weight ratio that combines with a lightness to make them one of the safest and easiest to handle access-system components available to the market.

Fibrelite offers the following product families, all of which have proven to be innovative, practical and durable in the wide range of applications around the globe:

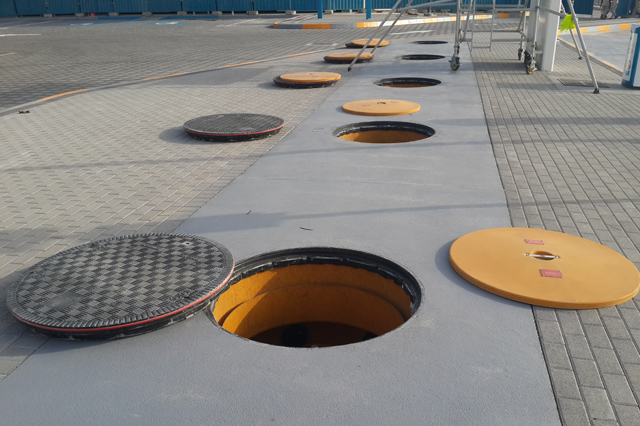

- Manhole Covers: A patented internal-structure and high-strength, one-piece molded design allows Fibrelite manhole covers to be made in a wide range of shapes and sizes that still allow load-bearing capacities up to 90 tons. This makes them ideal for use in sewage systems, drainage networks, electrical junction boxes, water treatment plants and on retail forecourts.

- Steam Covers: These lightweight, strong and corrosion-resistant access covers provide safe access to steam utility vaults. They have excellent thermal-gradient properties that prevent them from heating to dangerous levels from the steam vault below or direct sunlight above, which mitigates against the risk of burns when the covers are located on public sidewalks, crosswalks and other high-traffic areas.

- Dispenser Sumps: Fibrelite’s vacuum-testable dispenser sumps ensure a watertight installation while offering a strong, robust, liquid-tight containment solution that will last for the lifetime of the site. Unlike polyethylene, FRP will not deflect under groundwater pressure or lose rigidity in extreme temperatures. They are also fully conductive for enhanced safety.

- Remote and Direct Fill Sumps: Available for both above and underground setups, these sumps are designed for use with systems where direct fill into a tank is not feasible. The sumps are completely pre-piped and the FRP construction provides a flat sealing face that eases and optimizes the installation of penetration fittings, creating a watertight sump.

- Trench Covers: Fibrelite’s expansive portfolio of trench covers has a load-rating range of 250 to 202,000 pounds. While providing unparalleled performance from sidewalks to airport runways, the trench covers are light enough to be removed by hand while being resistant to water, corrosion, heat and skids.

- Tank Sumps: These truly watertight sumps are available in round, square and rectangular shapes in sizes from 45 to 60 inches in diameter and 45 to 48 inches square, all of which can be designed for use with all tank types, including fiberglass, steel and polyurethane-coated steel. The one-piece, molded FRP design allows for the easy, leak-free installation of entry boots.

- Underground Enclosures & Transition Sumps: Ideal for the forecourt, pipework, cable-transition chambers, conduits and electrical equipment, this range of corrosion-resistant FRP enclosures and boxes provides durable, watertight protection. They are designed to withstand harsh environmental conditions and are available in both conductive and non-conductive configurations.

Protecting People, Protecting the Environment and Enhancing Business Performance are the three foundational pillars of OPW’s Defining What’s Next philosophy of ensuring adherence to strong Environmental & Social Governance (ESG) operating principles. Fibrelite’s full range of access-system components aligns perfectly with OPW’s goal of assisting their clients in meeting the demands of the “Defining What’s Next” doctrine.