Imagine looking upon a commercial fuel site from a distance — so that you see the fuel island terminal, the dispensers, and the back office where the fuel site controller and tank gauge are frequently housed. Now imagine closing one eye. What comes into view after closing one eye becomes significantly reduced, and you no longer have a comprehensive view of the fuel site, right?

Commercial, fleet, government, bulk and retail fuel site managers who don’t reconcile their inventory are essentially operating with one eye closed.

Comprehensive site reconciliation that accounts for all fuel being pumped into and out of tanks is critical to achieving true fuel control. Without it, site operators lack timely visibility of common inventory problems including theft, fraud, leaks, meter drift, short deliveries and gray loads, all of which cause variance in fuel inventory. Difficult to detect, these unaccounted fuel losses have the potential to devastate a fuel manager’s bottom line.

Although inventory losses are frequently minor in comparison to the total inventory at the time, the losses are often incremental, accumulating over a long period of time. For example, the City of Cape Coral, Florida, performed a fuel management audit for the years 2006 to 2010. Fleet managers there did not obtain inventory measurements before and after bulk deliveries to verify that fuel delivered was the fuel received and did not use their fuel management system’s data trending abilities to oversee that transaction data was complete and accurate. Information obtained from financial reporting applications showed that, over five years, the City of Cape Coral paid $31,693 more for fuel than records showed being allocated to user departments.

With decades of experience helping retail, commercial, government, bulk and fleet fueling operations take control of their fuel inventories, the fuel management experts at OPW have witnessed firsthand how variance, if left unchecked, can deplete a fueling operation’s bottom line. Three particular causes of variance — meter drift, fuel theft and short-changed deliveries — are especially challenging to fuel site operations that are not supported by a powerful reconciliation program. Here’s a closer look at how these three stealthy sources of inventory losses drain operating budgets and how fuel management software, such as OPW’s Phoenix® Fuel Management Software, can help minimize financial losses.

Reconcile to Minimize the Impact of These 3 Potential Inventory Losses:

1. Meter drift — time is not on your side.

Throughput has been shown to weaken meter calibration — the more throughput a dispenser pumps, the more likely the meter is to be out of tune. This depreciation is known as meter drift. Most meters that depreciate give away fuel (as opposed to dispensing too little fuel). While the loss per meter may seem minor, the fuel lost over time can add up to a significant loss.

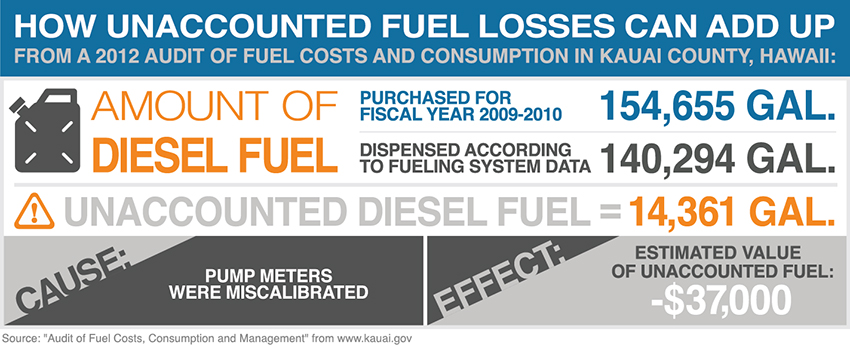

For example, a 2012 audit of Kauai County, Hawaii, fuel costs and consumption showed that the county purchased 154,655 gallons of diesel fuel for fiscal year 2009-2010, but fueling system data showed that only 140,294 gallons were dispensed, for a total of 14,361 gallons that could not be accounted for. The majority of that loss was later attributed to pump meters that needed to be recalibrated. With the national average of diesel fuel prices hovering around $2.57 a gallon in 2009, that difference equated to approximately $37,000 worth of unaccounted fuel.

In most cases, visibility into the calibration of dispenser meters is only available to meter technicians and Weights and Measures engineers, and therefore, it is very difficult for the fuel site operator to detect meter drift. A quality reconciliation program will analyze the over/short inventory data, enabling fuel site managers to identify meter drift and promptly schedule a meter recalibration.

2. Stolen goods — halt fuel theft before it gets out of hand.

An integrated fuel control system is a solid first line of defense against fuel theft at a commercial fuel site since drivers who know they are being held accountable are less likely to try and steal assets. However, card fraud and unscrupulous fueling practices still happen — particularly in the public works sector. And like meter drift, fuel theft often represents a minimal loss in the short term, but frequently occurs over an extended period of time, making the inventory losses not only difficult to detect, but accumulative.

Case in point: City of Belmont, N.C., officials didn’t realize that $60,000 worth of fuel had been stolen in 2010 until officials began reviewing Public Works Department fuel costs during budget discussions two years later. In 2011, Hawaii County officials discovered that over $100,000 worth of fuel had been stolen from the Department of Environmental Management. The theft, which was estimated to take place over the course of two years, was eventually noticed by a Department of Public Works bookkeeper, who observed an increase in county fuel purchases.

Reconciliation software helps fuel site operators get to the root of the losses much sooner — long before auditors review financials. The sophisticated data analytics available in most reconciliation software — including OPW’s Phoenix software — automate analysis procedures, enabling managers to identify potential instances of theft and initiate corrective actions much sooner in order to minimize financial losses.

3. Short-changed deliveries — site operators need delivery data they can trust.

Because accounts of unscrupulous delivery services haunt the fuel industry, fuel site managers who don’t reconcile their inventory struggle to have any measure of certainty that their inventory deliveries are on the up-and-up. From stories about drivers using mattresses inside their tanker to absorb fuel that they later re-sell, to meters rigged on delivery trucks in order to inflate supply numbers, today’s fuel site operators need much more than a bill of lading to know they are getting what they paid for.

Automated fuel management software programs that facilitate real-time reconciliation of fuel from tanks and dispensers are the industry-leading solution for obtaining up-to-the-minute inventory levels. In addition, software programs that offer comprehensive site reconciliation are more accurate than manual statistical inventory analysis. For example, OPW’s Phoenix Fuel Management Software has the ability to account for fuel dispensed while a delivery is in progress. Manual reconciliation procedures literally require an operator to record tank inventory readings and dispensed quantities at exactly the same moment — an extremely difficult feat to accomplish.

To learn how OPW’s powerful fuel management software, Phoenix, can not only reduce financial losses caused by meter drift, fuel theft and short deliveries but significantly streamline manual reconciliation procedures, call OPW Fuel Management Systems today at (708) 485-4200 and ask to speak with the Commercial District Manager from your region.

This article is part of OPW’s educational series, Focus on Fuel Control, designed to educate distributors, customers and end-users about trends and challenges facing commercial, terminal, fleet and government fueling applications. Visit the Focus on Fuel Control page regularly to read future articles from the Fuel Management experts at OPW.