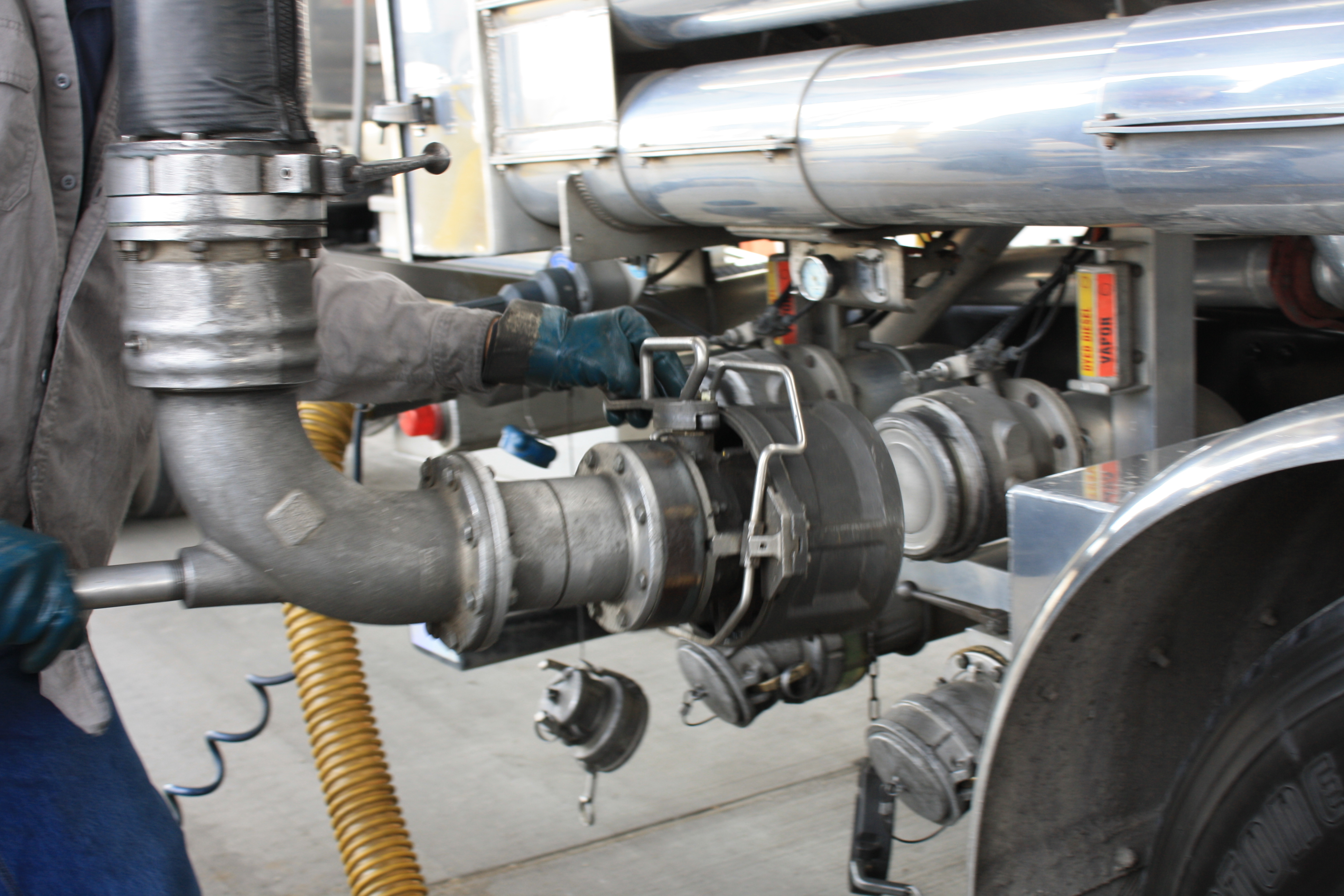

Nothing in your terminal is subjected to use and abuse like an API Coupler. In many high-volume terminals, couplers can be connected 50 or more times each day. That’s 50 head-on collisions with a truck adaptor in a single day’s work. Today’s couplers (aka "load heads") are designed to stand up to this heavy usage, but there are questions you should ask to make sure your couplers, and your operation, continue running smoothly.

Is Your Coupler Leaking?

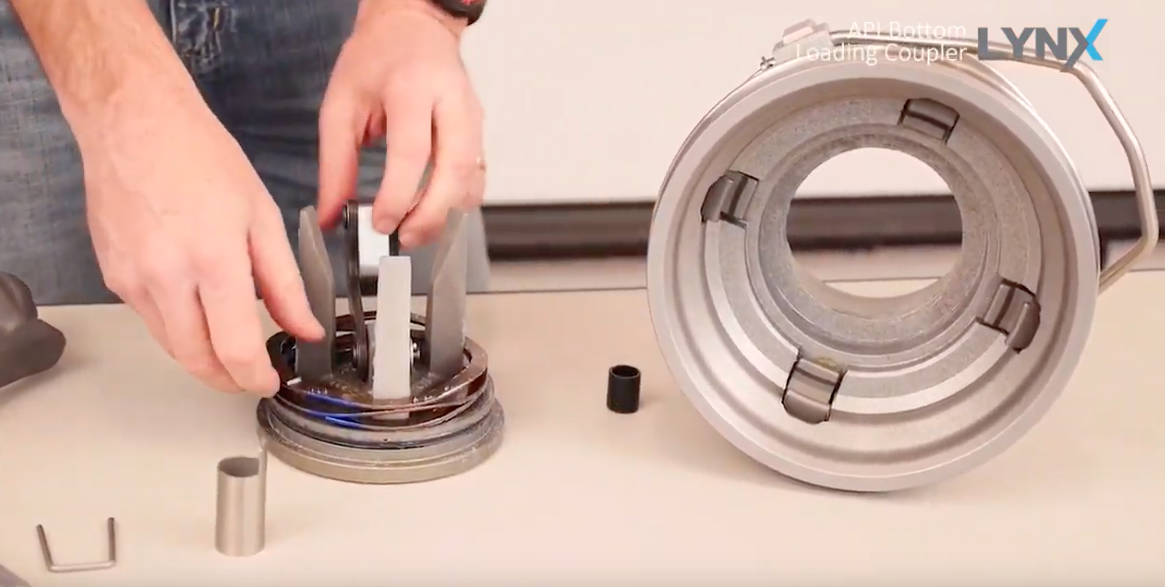

If so, the situations in which it leaks are important to monitor. Does the coupler leak while connected to a truck? A minor leak here could indicate seal wear, specifically related to the nose seal, the primary seal between the truck and coupler. Loading arm adjustment could also contribute to a minor leak. Ideally, loading arms should be balanced at the truck adaptor height of 30-35” off-grade. A major leak might indicate a weak or broken wave spring. Wave springs provide seal compression when connected to the truck adaptor. In this case, you would have to take the coupler out of service to inspect or replace the wave spring.

Another possibility for a leak is leaking while parked. Minor leaking while parked could also be due to seal wear, but it may signify greater problems. Thermal expansion can affect API Couplers if thermal reliefs are not in place and functioning, pushing them to much higher pressures than their typical rating of 75-80 psi. It is possible that couplers could experience 300, 400 or even 500+ psi during extreme thermal expansion. This can cause seal damage, or even worse, catastrophic failure. A difficult to open and close handle can be a sign of thermal damage.

Temperature, specifically cold weather, can be the culprit behind some leaks. Regardless of temperature, your terminal must keep flowing, and though today’s seals are generally reliable in temperatures to 0°F, you may need additional protection. Special cold-weather seals designed for extreme cold can keep your couplers in operation well below zero. If your couplers are leaking in cold weather, verify the seal material and consider a lower temperature option.

Are You Having Trouble Connecting to the Truck Adaptor?

Check the latches and cams of your couplers. These areas are very prone to dirt and debris buildup, and they can cause your cams to face difficulties, especially in winter months.

More Questions? We’re Here to Help!

These are just a few tips to hopefully improve your terminal operation. If you would like to watch any of our maintenance videos, please go to the

OPW Engineered Systems YouTube page and search API couplers.

For more information, you can always check out the Tech Support or Resources sections on our website at

www.opw-es.com or call us at +1 513-932-9114 or 800-547-9393.