Developers of innovative new products or systems are understandably proud. It is the truly trendsetting developers, however, that immediately begin to look for ways to make their new product even better. In this vein, Belanger, Inc., a product brand of OPW Vehicle Wash Solutions, has made many significant improvements over recent decades in the wash media used in conjunction with its wash systems.

Over the years, the wash media evolution has progressed from hard plastic, or nylon brushes, to brushes that were actually constructed of soft strips of cloth and, later, closed-cell foam media. These designs better protected vehicles from damage, real or perceived, while providing an elevated level of clean. After that, high-RPM closed-cell foam media was another step forward from soft cloth because it didn’t hold water or dirt, remained lighter and provided a gentler wash experience for the vehicle. Though traditional foam is a worthy innovation, it only cleans with its tips and needs to be spun at higher RPMs for the wash media to fully extend, allowing the tips to properly contact the vehicle. Because of this particular shortcoming, there remained room for improvement, including a reduction in the amount and level of ambient noise created during the friction wash process.

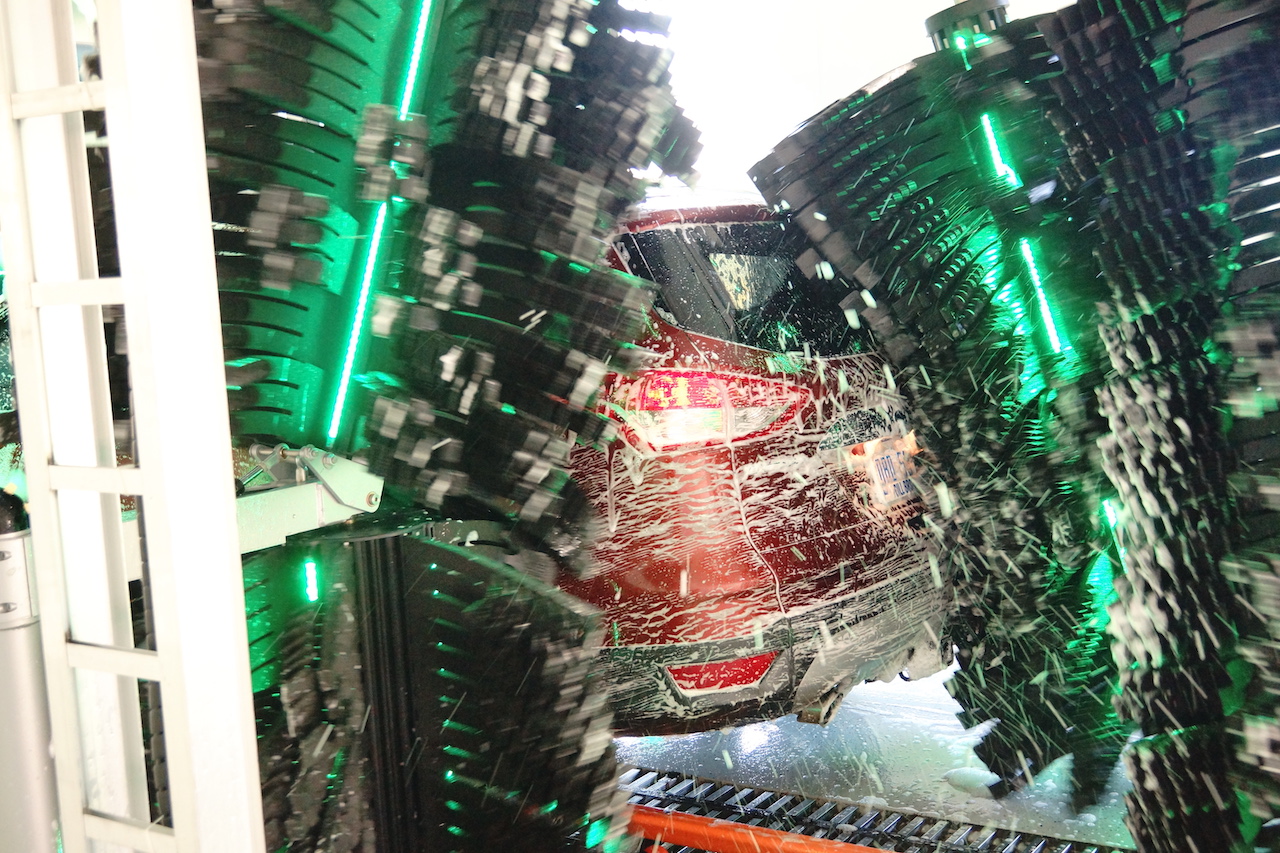

Recently, Belanger developed the answer to building a quieter wash with its SpinLite® Vehicle Wash System. The SpinLite system is outfitted with patented, slow-spinning ShineMitt wash media. The self-supporting ShineMitt wash wheels spin at one-third the speed of traditional wash wheels, but still deliver an exceptional level of cleanliness with reduced noise and further reducing the risk of vehicle damage.

The ShineMitt media has fingers that contour on contact with the vehicle, which exposes multiple cleaning edges that can lift dirt and grime from the vehicle’s surface. This enables the ShineMitt to perform more than four times the cleaning touches of traditional media. The low-frequency sound that is produced during the wash process is also easier on the ears of drivers, their passengers and any technicians that may be in the vicinity of the wash when it is operating. A quieter wash can also leave drivers more relaxed, less anxious and apprehensive, and able to better enjoy the wash experience, which also raises the likelihood that they will become repeat customers.

Two other SpinLite features that improve the wash experience for both the driver and site operator are:

- SpinLite Core: A component grouping that fits almost any site footprint, while delivering an unmatched clean and shine, without the need for equipment redundancy that can compromise efficiency and cost effectiveness.

- Active Site Marketing: Uses patented LED-illumination hubs with color-changing lights and motions to attract more customers, night or day.

Since 1969, Belanger, Inc., has been a leader in the design and development of conveyorized tunnel-wash systems. Belanger’s tunnel washes were among the industry’s first to deploy soft-touch wash media that deliver a best-in-class wash experience and reduced risk of vehicle damage while possessing the ability to wash more than 200 vehicles per hour. SpinLite is Belanger’s latest innovation that is expanding the capabilities of tunnel systems – from both a wash-performance and wash-marketing perspective.