By their nature, design engineers are hands-on people. The members of the engineering team at OPW Engineered Systems like nothing more than packing up their measuring and surveying tools and heading out to a bulk-plant or terminal site where they can begin the process of designing and creating yet another best-in-class solution for a difficult fluid-handling challenge.

Since March, that inherent wanderlust has been dampened by the sobering realities of the COVID-19 pandemic, which has seen lockdown and shelter-in-place orders mandate that non-essential travel be curtailed and “work-from-home” become the new normal – at least for the near future.

While this required many ingrained habits to be reconsidered or changed, the world kept spinning, and OPW Engineered Systems clients in essential industries still needed to satisfy the requirements of their own customers through the implementation and use of optimized fluid-handling equipment and systems. So, the engineers of OPW Engineered Systems took stock of their new reality and readily adapted to the inevitable changes (and challenges) that would be part and parcel of a work-from-home world.

The first step that laid the groundwork for this new way of doing business was to immediately reach out to all clients to let them know that OPW was still available to assist them with any of their needs, from shipping a replacement part to designing, manufacturing and installing a new loading-arm system, no matter how tight the deadline. With face-to-face meetings discouraged, the engineers deftly adjusted to virtual site visits and chats with their clients. This allowed them to view the location remotely and compile the necessary measurements and gather all of the other pertinent information that would be needed to produce detailed architectural drawings. That would then allow the selection of the best components for the application and enable a quote to be produced and a production timeline to be established.

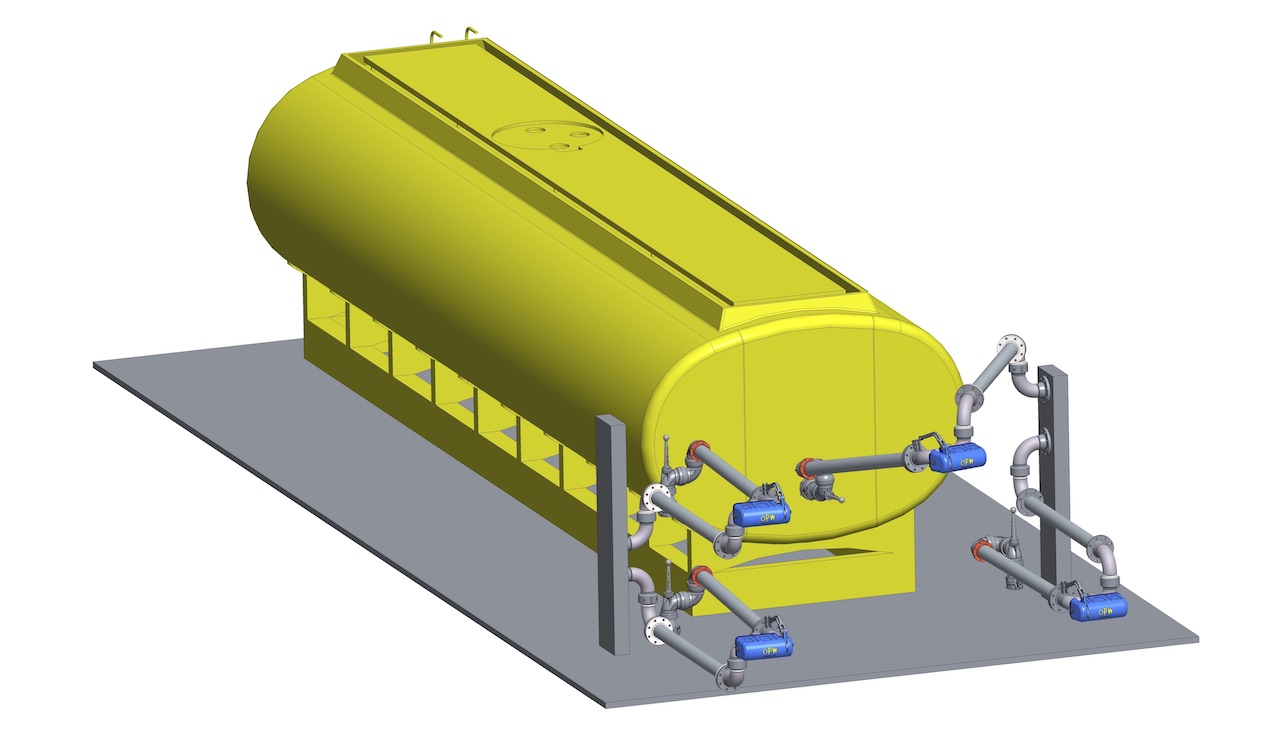

In one specific example, a string of email communications from a client set the groundwork for what was needed with a series of virtual site visits leading to the development of precise product drawings and a layout configuration that would show exactly how the system would be situated and how it would operate. This was especially important because the facility required a highly engineered and customized solution. The client so satisfied with OPW’s capabilities that four loading-arm systems were eventually ordered.

The moral of the story is that while the COVID-19 pandemic knocked everyone back on their heels and demanded new ways of confronting old tasks, providing the best “service” remained the fulcrum of a successful client relationship. Though there was very little person-to-person communication in the cited example, the result was still a truly “engineered” system, one that meets the high standards of quality that OPW Engineered Systems has been providing for more than 125 years.

This is also another illustration of how “Defining What’s Next” is so much more than just a catchy slogan; it is the foundational DNA that enables companies like OPW Engineered Systems to consistently meet or exceed the expectations of its customers who seek the best solutions for the most demanding fluid-handling applications.