The fluid transfer experts, OPW Engineered Systems has designed dry disconnect couplers and adaptors to protect against product loss in the most challenging environments. One dry disconnect

system in particular, Drylok,

features a rugged design that promotes excellent flow with little loss of product.

To make the most out of the Drylok coupler and adaptor system for use with various fluids such as ethylene oxide, sulfuric acid and other hazardous materials, it is important to understand these operating and handling procedures:

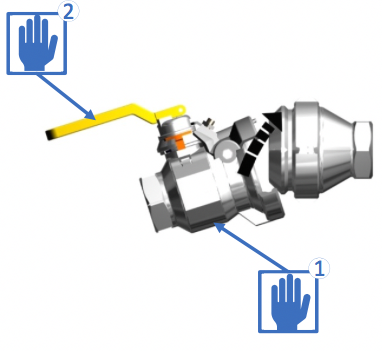

- Prior to connecting the coupler to the adaptor, lift the coupler using both hands: place one hand underneath the coupler (1) and the other on the handle (2). Lift the coupler, angling the mating end upward.

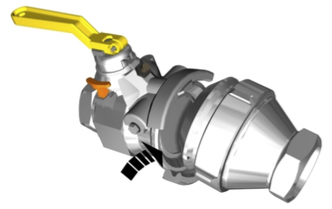

- Bring the coupler towards the adaptor mating end at that upward angle, where the coupler’s jaw would engage the bottom of the adaptor’s nose first.

- Once the jaw is engaged to the bottom of the nose, bring the body of the coupler in line with the adaptor by using the handle and push to engage the clamp to the top of the adaptor’s nose.

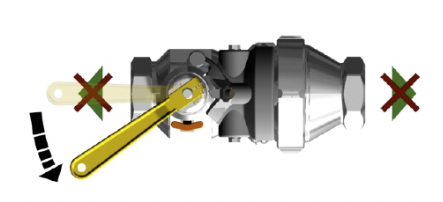

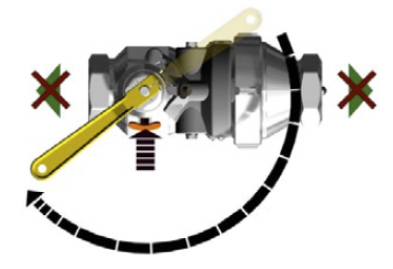

- To lock the connected system in a closed position, view the connected system from the top, where the coupler is on the left and the adaptor is on the right, turn the handle counterclockwise until the lock engages.

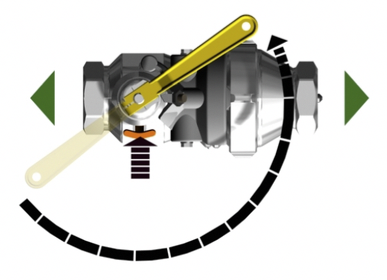

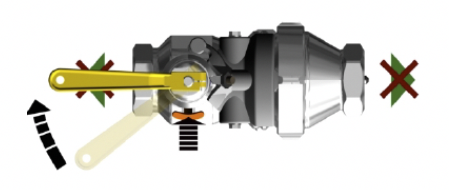

- To open the system for product flow, press the safety release button on coupler down and turn handle counterclockwise until it locks.

- To close the system, press the safety release button on the coupler and rotate the handle clockwise until it locks.

- To disconnect the system, press the safety release button on the coupler and turn the handle clockwise so that it is parallel with the coupler. Press down on the clamp’s tab (opposite side of safety release button) and push down on the handle to disengage the system.

When used properly, in a fully interlocked position, Drylok is an ideal tool for the safe transfer of hazardous, corrosive and volatile liquids. SI Group, a leading manufacturer of phenol-based products, trusts Drylok for their loading operations due to its features and benefits that aim to keep technicians out of harm’s way.

OPW Engineered Systems has established a position as a complete provider of fluid transfer equipment, including dry disconnects, loading arms, swivel joints, electronics and accessories. To learn more about OPW Engineered Systems, go to www.opw-es.com.