18 January 2017

First of all: Our purpose with this list is not to make a laughing stock out of anyone, but rather to kindly remind everyone that even with a durable high quality product, everyone involved in transportation, storage, on-site handling, installation and testing, needs to understand that there are limits and that the recommendations we publish as a manufacturer and supplier of retail fueling piping are for everyone's benefit.

Unfortunately, all of the things on this list actually have happened, although it has taken many years and involved a lot of people to make it this extensive. It has truly been a global effort!

1. Don't weld a wet pipe

The water droplets will boil at 100°C and welding heats the plastic to 200°C. You may get burned and the weld may not be tight.

2. Don't smoke while doubling as a human clamping tool

There may be fuel spill or vapors anywhere even if a station is closed for an upgrade. And it is very hard to sit motionless for the complete 30 minutes of cooling time, especially when smoking.

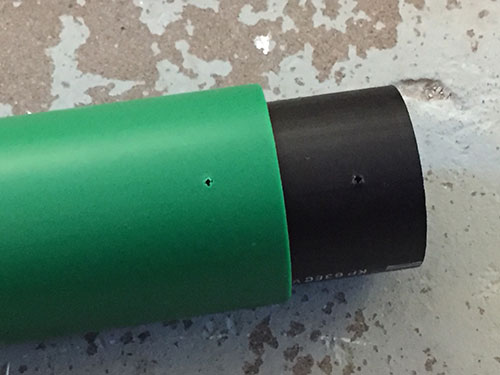

3. Don't put a nail through the double wall pipe to prevent the inner pipe from dislocating during transport.

Even if you remove the nail after delivery, there is most likely a risk that it left a hole in the pipe.

4. Don't bend the pipe so much that it kinks

Even if you are this impressively strong, don't leave the pipe like that. Just don't. There will be flow rate issues.

5. Don't step on a pipe that was just welded

Yes, you need to get out of the sump, but try to find another way. In less than 30 minutes the weld will be super strong but right now it is soft and needs time to cool down.

6. Don't run the pipe over with a truck

It just may break.

7. Don't weld metal things next to the pipe

The pipe is plastic. Plastic can melt. Or catch fire.

8. Don't throw pipe coils off the truck during delivery

Someone might see the damage you cause.

9. Don't work the pipe over with an hydraulic pick.

You may cause a hole.

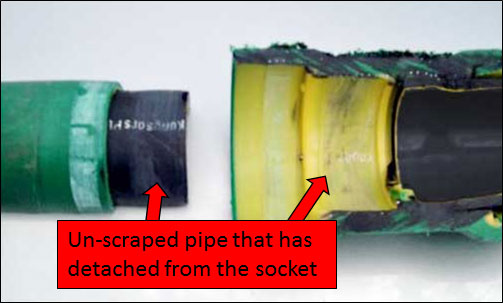

10. Don't cheat with scraping

It may be your fault the tightness test fails on the last day.