Source: Chemical Products Finder

Minimizing the amount of chemicals lost during the connection and disconnection of coupling systems is a significant benefit to the health of the environment and operators, but it can also provide substantial cost savings. High-value chemicals are used throughout the manufacturing industry and utmost care must be taken to reduce any losses to maximize profits. This article from OPW Engineered Systems discusses how dry disconnect coupling systems can help reduce the risk of handling these high-value chemicals.

Butadiene. Xylene. Toluene. Sulphuric Acid. Potassium Hydroxide. Even the names of these hazardous chemicals sound dangerous. In addition to potentially harming the health of humans and the environment if mishandled, they have another thing in common: they are very expensive to produce.

That is why manufacturers, processors, shippers and distributors of highly hazardous, high-value chemicals enter into a tacit agreement with their employees, the environment and bank accounts: these incredibly volatile and valuable fluids must be handled with the utmost care, from the manufacturing plant through the railcars and tanker trucks that ship them and the bulk-storage facilities that house them, lest any damage be done to any of their constituent parties.

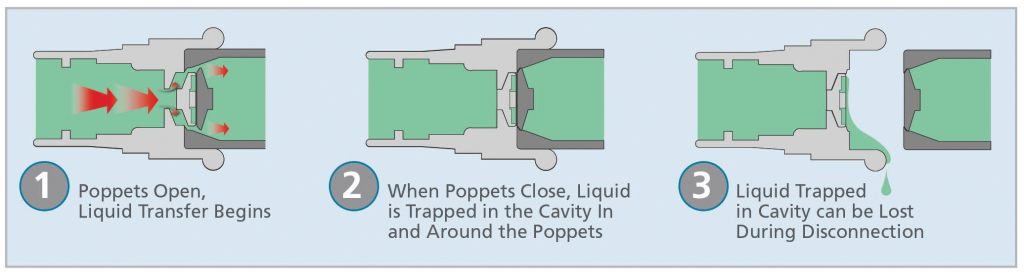

Figure 1 Poppet Style Design

A key link in the chemical-processing supply chain is the equipment that is used to facilitate the transfer of volatile chemicals from the manufacturing facility to transport vehicles and then to the storage terminal. For years, the accepted technology for the dry disconnect couplings that would enable the connection of hoses to storage tanks and transport vehicles has featured a poppet-style design.

The use of poppets, however, can compromise safety and create potential problems for the handler who is looking to ensure the safety of employees and the environment because the shape of the poppets inside the coupler housing form areas where chemicals can nest, meaning that there will always be the possibility that some type of product spill can occur when the couplings are disconnected. This is not a big issue if the fluid being handled is non-hazardous and inexpensive, but a potential problem when handling hazardous and high-value fluids.

Fortunately for the handlers of dangerous chemicals, there is an alternative dry-disconnect coupling technology that addresses all of the operational shortcomings that are inherent in poppet-style coupling designs. It is called the Epsilon Dry Disconnect Coupling from OPW Engineered Systems, Lebanon, OH. What sets the Epsilon apart from traditional coupling technologies is the use of a ball-valve design instead of poppets to facilitate opening and closing of the coupling.

When utilizing poppet-style disconnects, (see Figure 1). liquid transfer is initiated when the poppets are opened by the operator (Step 1). The liquid-transfer is completed when the operator closes the poppets (Step 2). However, at this time, a small amount of liquid can be trapped and during disconnection, it is possible that the trapped liquid can escape, leading to a minor product spill (Step 3). When hazardous, high-value chemicals are being handled, this potential product spill can be harmful to site personnel and the environment.

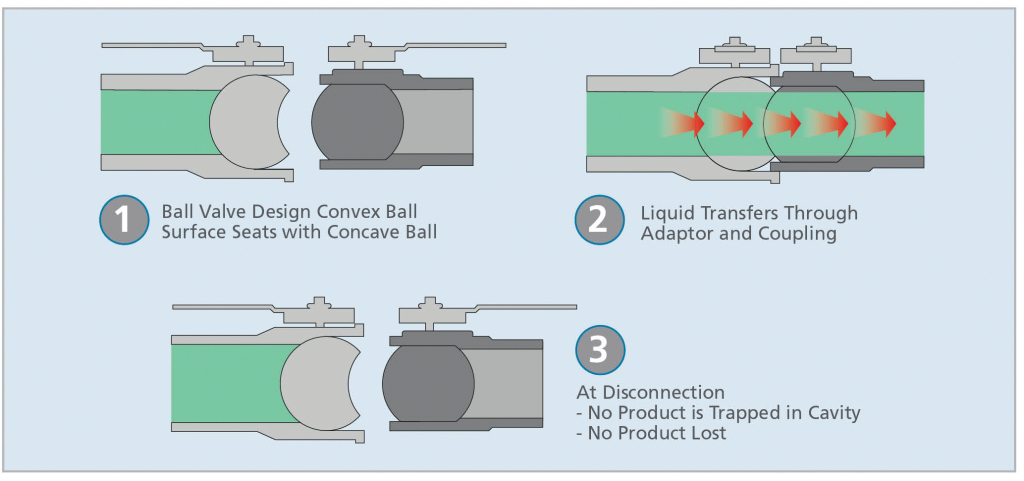

Figure 2 Ball Valve Design

The unique ball-valve operation (see Figure 2). of the Epsilon disconnect allows a convex ball to seat with a convex ball when the valve is opened (Step 1). This straight-through design allows the liquid to transfer through the adaptor and coupling with no reduction in flow rate (Step 2). Upon disconnection there are no cavities created in which product can nest, meaning no product will be spilled (Step 3). This no-spill operation is accomplished through the use of five independent and redundant mechanical interlocks that require deliberate sequential action by users, thereby eliminating unintentional spills and catastrophic chemical releases.

In addition, the Epsilon was also engineered for easier maintenance when compared to a poppet-style design. The Epsilon allows for quick replacement of the transfer seal without any lockout. This helps minimize downtime when replacing the seals, stems and bearings. Also, no special tools are required for replacement of the seals.

When there is a demand for reliable transfer of hazardous, high-value chemicals, the ultimate choice is the Epsilon Dry Disconnect Coupling from OPW Engineered Systems.

Other standard-setting features and benefits that enable the Epsilon Dry Disconnect Coupling to stand apart from the competition include:

- Straight-through fast-flow design for optimized loading/unloading times

- Seals, stems and bearings are easily replaced for like-new performance with minimal downtime

- Wetted components available in SS-316 or Hastelloy C

- Spring-loaded and spring-energized PTFE, TFM or PFA seals

- Optional keyed interface isolates transfer lines, preventing product cross-contamination

- Available in 1", 2" and 3" sizes.

David Morrow

Director of Product Management OPW Engineered Systems,

part of Dover Corpn’s OPW Divn

Tel: (800) 547-9393

E-mail: David.Morrow@opwglobal.com.

Website: www.opw-es.com.